Cold Expansion Solutions for Aircraft Maintenance and Life Extension

The aviation industry faces constant pressure to extend the service life of aircraft while ensuring safety and minimizing repair costs. Cold expansion solutions offer a proven method for increasing the fatigue life of fastened joints, reducing structural damage, and preventing corrosion. These techniques are particularly valuable in aircraft maintenance as they provide a means to enhance damage tolerance, ensuring that components can withstand the stresses of flight for longer periods without compromising safety. By utilizing cold expansion, aircraft operators can reduce downtime, and increase the overall efficiency of their maintenance programs, while simultaneously extending the lifespan of critical parts.

Reinventing the Future of Cold Expansion

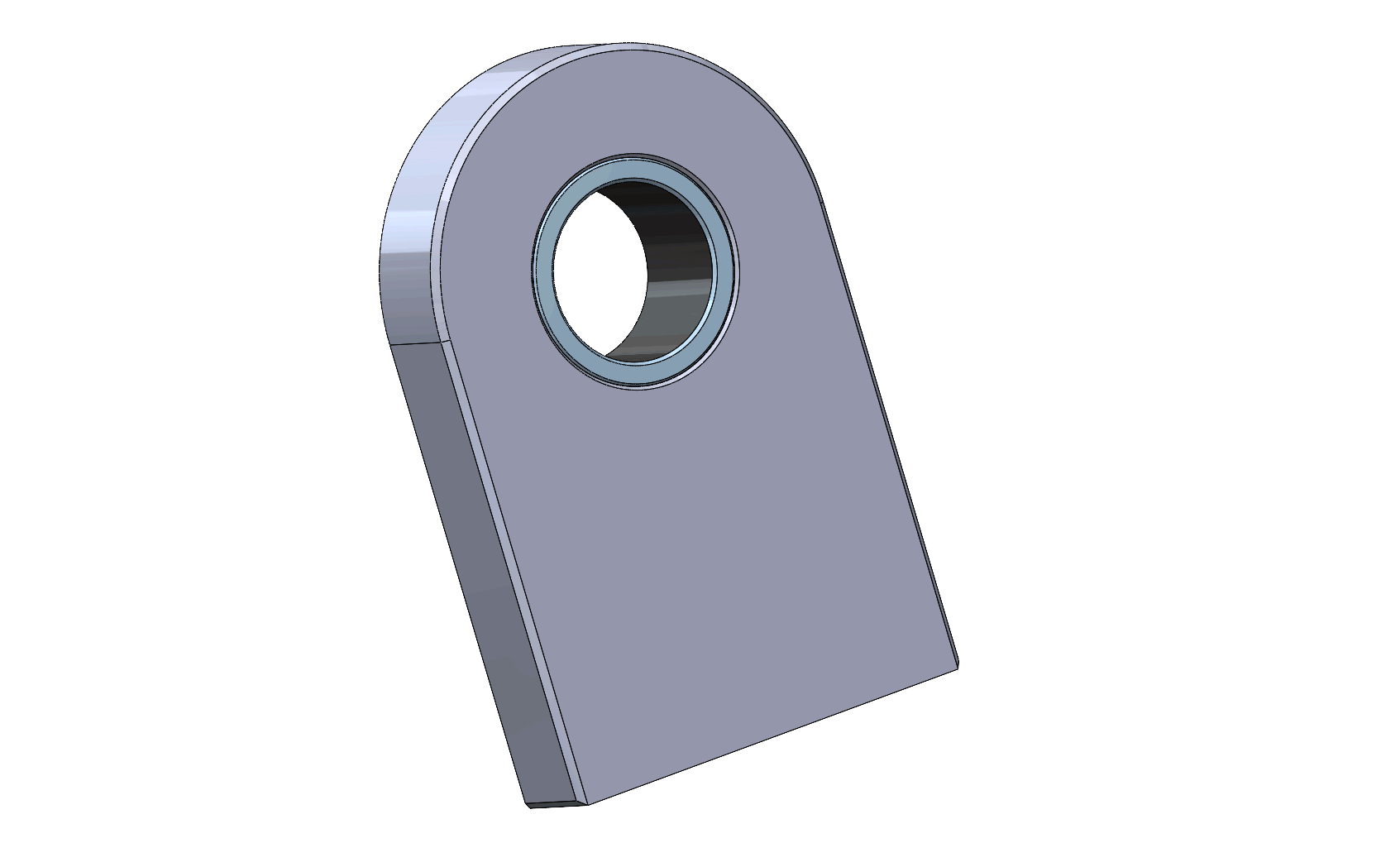

Expanded Aerospace Bushings

PartWorks expanded fit bushings offer customers a high-performance product with fast, turnkey installation. By eliminating error-prone installation processes, customers can enhance bushing and structural performance without damaging components through pressing or hammering, or exposing workers to cryogenic materials. Custom bushing solutions designed for fatigue life and damage tolerance enhancement can be validated through analytical and experimental expertise based on PartWorks testing data. Our bushings are available in common aerospace bushing materials like Cres, Al-Ni-Bronze, and Titanium, with various plating options based on customer needs. Custom configurations can include lubrication grooves, fluid ports, and other unique solutions, facilitated by our hand-held hydraulic tool.

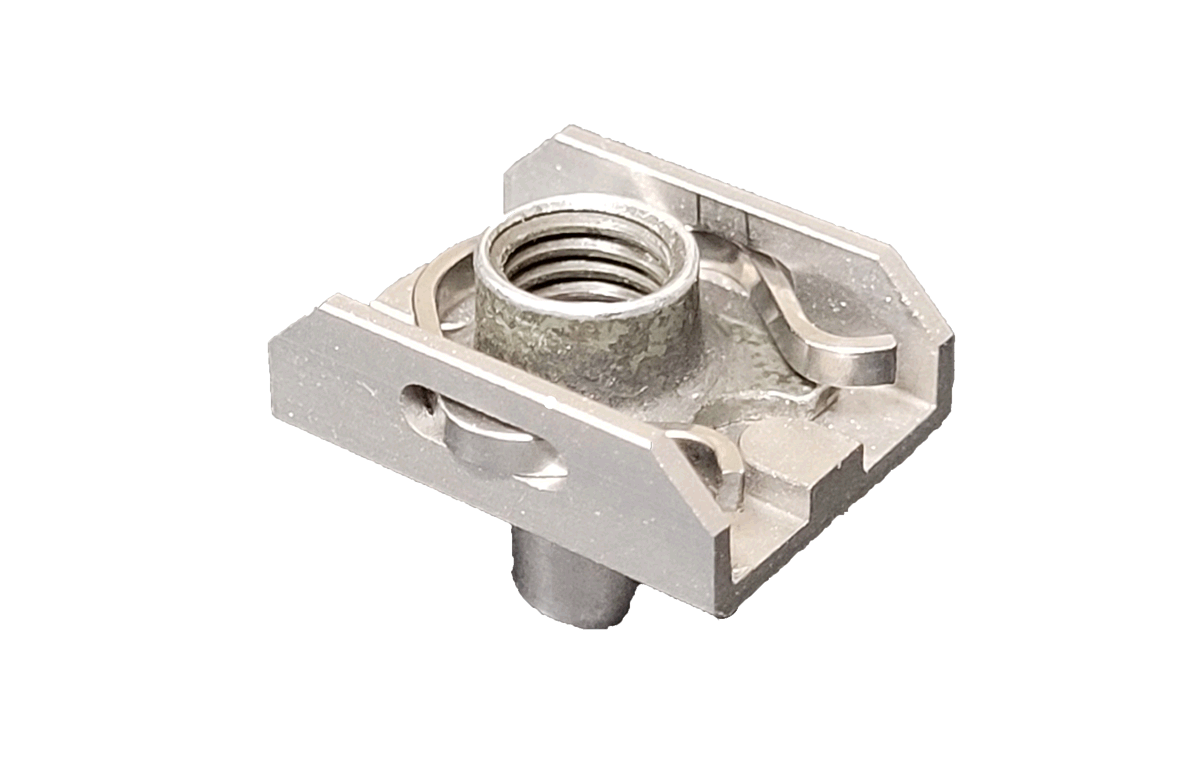

Ultra Thin-Walled Rivetless Nut Plate for Aviation

PartWorks bushed rivetless nut plates restore corroded holes to nominal sizes with minimal material removal, maximizing both cold expansion and life extension. Based on extensive research from ONR and AFRL, our solution demonstrates life extension improvements comparable to brand-new structures. In combination with our adhesive, this patented repair method provides a long-term barrier against further corrosion damage, delivering superior performance in harsh aviation environments.

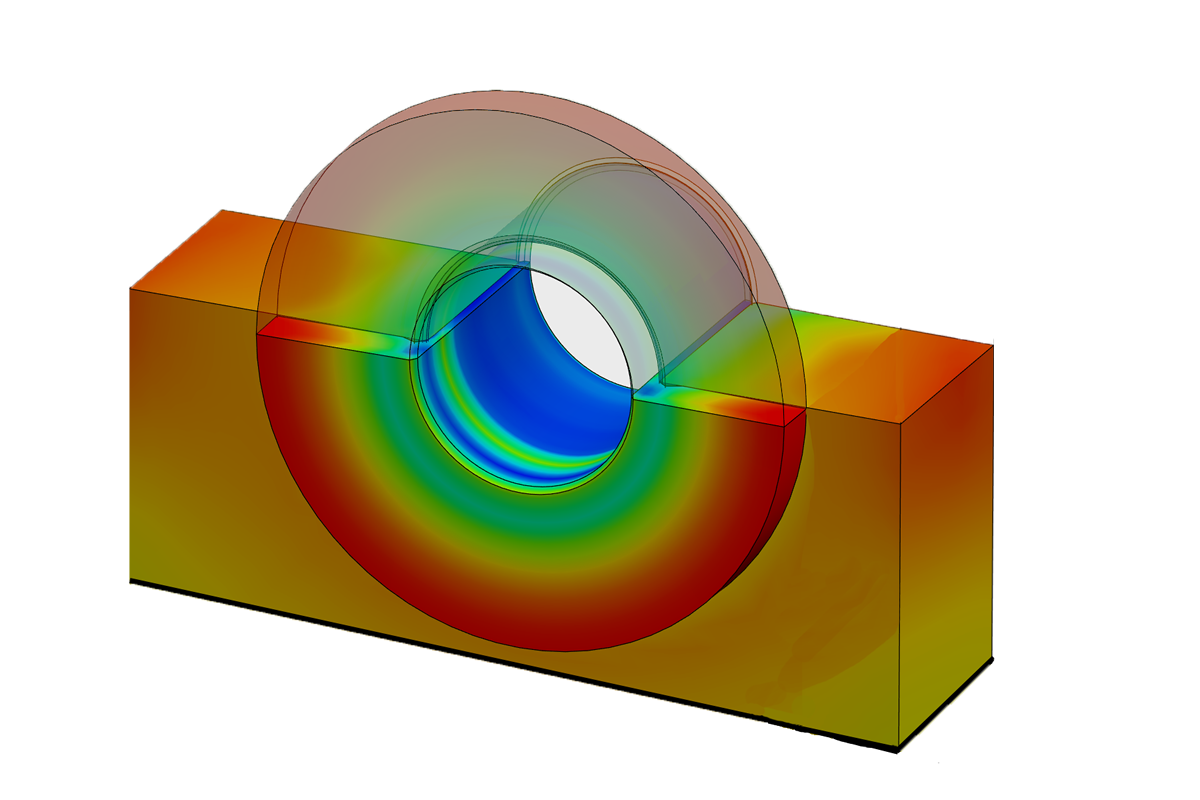

Engineered Residual Stress Solutions

PartWorks products provide residual stress solutions for the fatigue and damage tolerance enhancement of fastened structure or single pinned joints. We work with customers to identify the critical product and process parameters to drive the design solution. This can include applied interference levels, minimum compression in the structure or not to exceed tensile stress limits. The designed configuration can be evaluated with analytical models, FEA, as well as experimental techniques including digital image correlation (DIC) and physical testing to ensure that the product and installation function as desired.

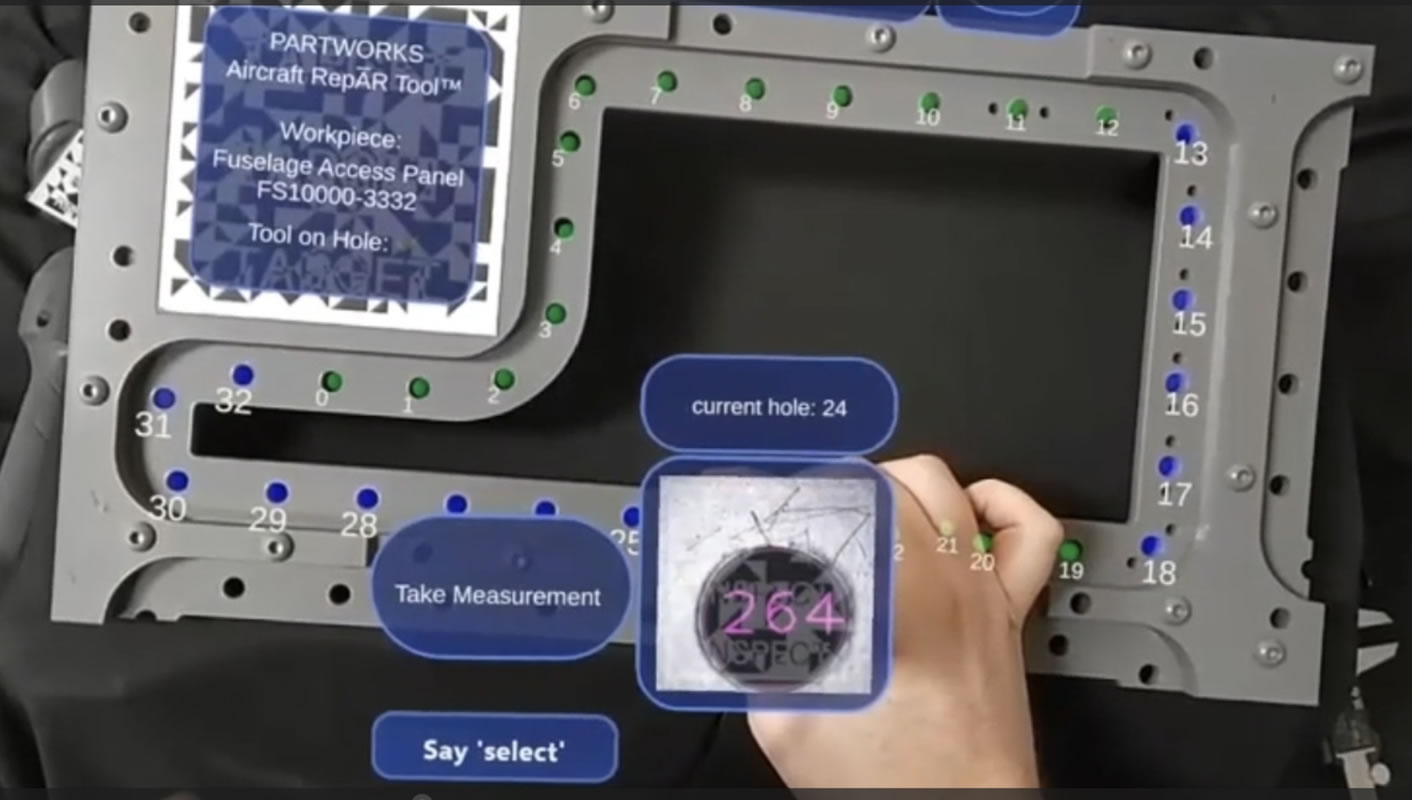

Handheld Smart Tools for Cold Expansion

PartWorks is pioneering the development of a high-performance handheld cold expansion tool. Data collected by this tool validates that each process is correctly executed, based on parameters derived from our fatigue test programs. This system ensures full documentation of repairs, supporting the case for life extension credit and demonstrating compliance with aviation maintenance standards. Our tool is a breakthrough in cold expansion validation, providing an intuitive and reliable solution for technicians.

Explore the possibilities