INTRODUCING

RepĀRTM Aircraft

Maintenance System (US Patent Pending)

Revolutionizing Aircraft Maintenance with Augmented Reality

Brought To You By

Where Augmented Reality Meets The DIgital Twin

Unlock the Future of Aircraft Maintenance Efficiency

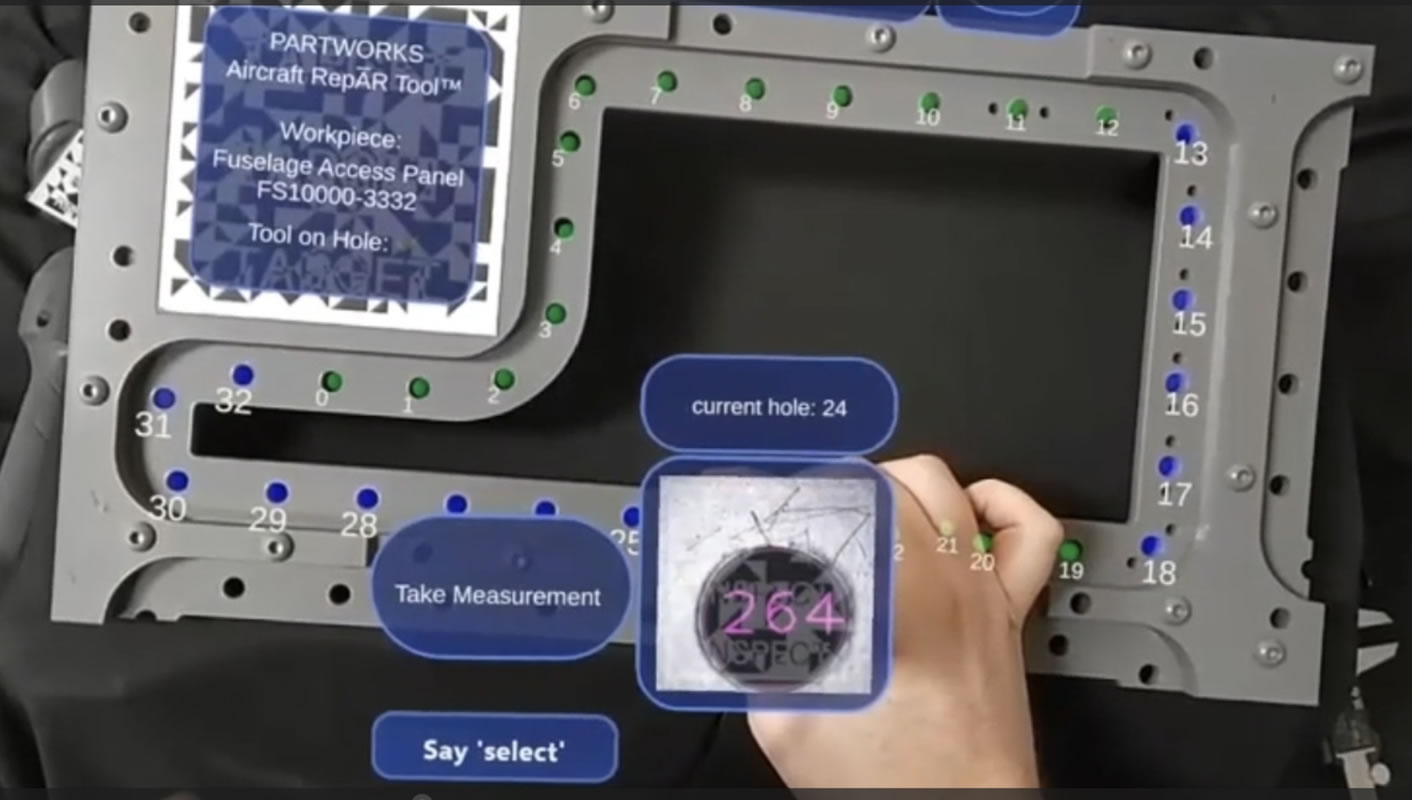

In the fast-paced world of aviation, precision, speed and documentation are paramount. Introducing RepĀR, the new Augmented Reality (AR) aircraft maintenance program by PartWorks.

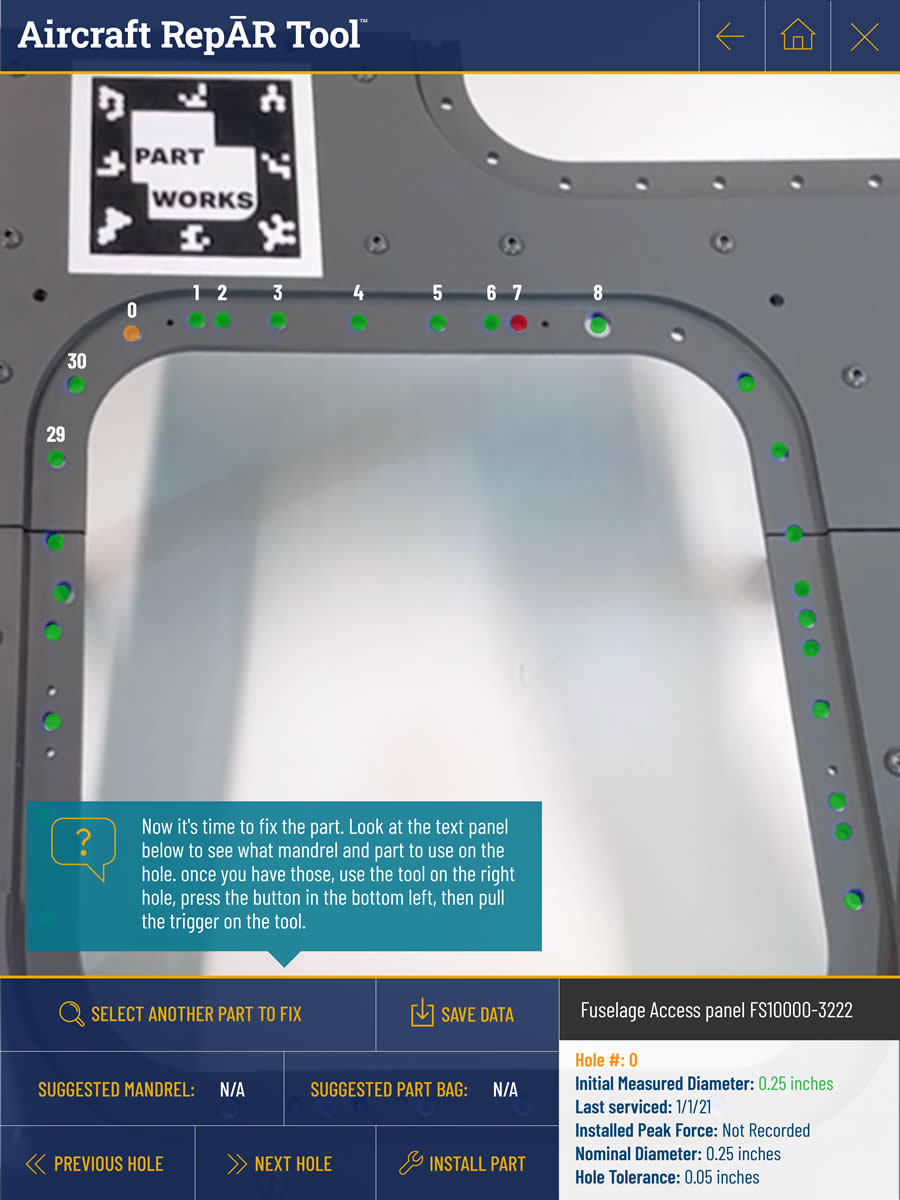

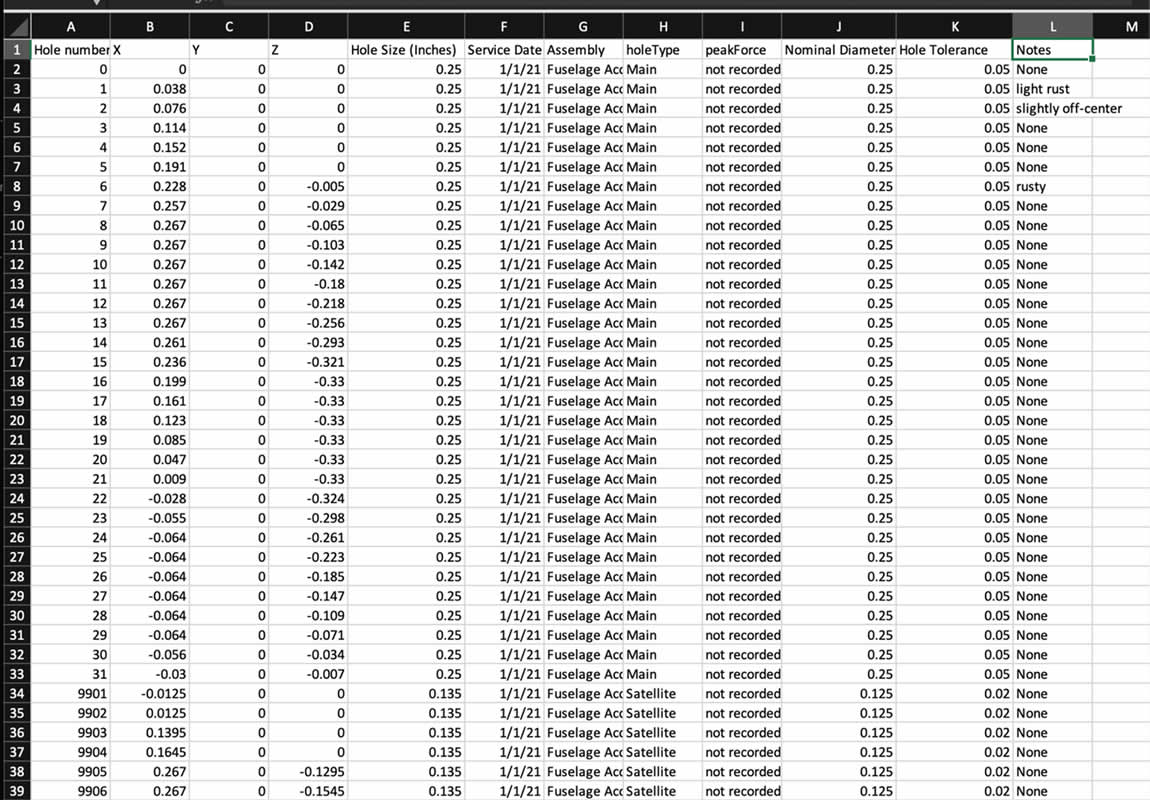

RepĀR leverages state-of-the-art technology to streamline repair and inspection of aircraft fastener holes, part installation, and processes with greater consistency using a patent-pending combination of Augmented Reality, Computer Vision, and Artificial Intelligence. RepĀR contributes data to your Digital Twins, reduces errors, improves operational efficiency, verifies process, tools, and parts then can generate comprehensive multimedia documentation for validation, certification, and training.

Key Benefits:

Rapid Digital Twin Generation:

- RepĀR simplifies the creation of digital twins with lightning speed, offering a comprehensive overview of fastener holes, structural data, and assembly operations.

- Accesses crucial information instantly, facilitating efficient decision-making and documentation in aircraft maintenance.

Local Coordinate Precision:

- RepĀR combines industry standard object tracking with a proprietary Area Of Interest capability that swiftly acquires structural data (e.g., holes).

- 3D models are NOT required, but if you have them, RepĀR will utilize and update your Digital Twin with new or enlarged holes.

- Also not required: predetermined coordinates, finicky laser/iGPS tracking systems.

Real-time Data Capture and Recording:

- Capture critical data, including dimensions, Non-Destructive Inspection (NDI) results, or cold expansion data, in real-time.

- All data is registered against an instantaneously-created relative coordinate system, providing conclusive proof-of-work completion, accuracy, and timing.

- Utilizes any device with a camera to define hole locations with millimeter accuracy, providing both written and visual records of the maintenance process. Ideal for flight worthiness and structural integrity tasks.

- Integrate RepĀR with enterprise data solutions using JSON, REST APIs.

Economical, Versatile, Compatible:

- RepĀR seamlessly integrates with commonly available connected tools like gauges, rivet guns, Eddy Current Probes, torque wrenches and other repair equipment using PartWorks Smart Object Trackers.

- RepĀR seamlessly integrates with commonly available devices like cameras, tablets, laptops, and AR goggles.

- All without the expense and complexity of lasers or GPS trackers.

- Use multiple external cameras for an unobstructed view of the work area.

Designed for a broad range of aircraft maintenance stakeholders:

- Quality Assurance (QA) teams can ensure the highest standards are met through process recording and data capture.

- Mechanics guided to enhance precision and efficiency.

- Manufacturing processes streamlined with error-free identification, even with Collaborative Robots (Cobots).

- Airworthiness, MRB Engineers and line supervisors can make informed decisions based on real-time, reliable data.

Empower Your Team,

Elevate Your Operations:

RepĀR revolutionizes the aircraft maintenance landscape, empowering your team with advanced technology that ensures accuracy, accountability, and efficiency. Say goodbye to cumbersome processes, expensive equipment and hello to a future where maintenance excellence is the norm.

Invest in RepĀR by PartWorks today and experience the transformation of your aircraft maintenance operations. Elevate your standards, elevate your performance with RepĀR!

The Future of AR Is Now

Want to learn more about PartWorks products and solutions?

Please fill out and submit this form and we will be happy to answer your questions.

You can also reach us directly by phone at (404) 910-3210.