CUTTING THE CORD TO THE PAST; CHARTING THE FUTURE TO INNOVATION.

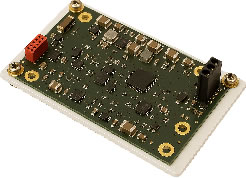

Introducing the PartWorks Precision FXTM (Patent Pending) Battery Powered Hydraulic Puller, (PFX15K). The most powerful connected, programmable puller on the market.

PARTWORKS

PRECISION FX

(PFX15K)

- BLDC motor technology for maximum power.

- Durable enclosed housing and double-insulated circuitry with fault detection for safe, quiet, reliable operation.

- High-power micro hydraulic pump with modular reservoir for flexible configurations.

- Adjustable stroke length for faster installs, clearance control, and versatile grip with one mandrel.

- On-board microcontroller for operations, setup, tool management, data acquisition, storage, and logging.

- Color LCD display for operator awareness, setup, and control.

- Interoperable with PartWorks RepĀRTM Augmented Reality Solution.

- Indexing rotation on dual axes for hard-to-reach locations.

- Industry-standard battery compatibility.

- USB and wireless connectivity.

PRECISION, POWER, PORTABILITY

ABOUT THE PFX15K

The PartWorks Precision FX is a pioneering, battery-powered, handheld hydraulic puller that delivers high force, long stroke, and fast actuation. Engineered for aerospace applications, this versatile tool eliminates the need for cumbersome hydraulic, pneumatic, or electrical lines, enhancing mobility, safety, and convenience.

PFX15K CAPACITIES

- 15k lbf. pull force

- 3.5 in. of stroke

- 5 second stroke time at full load

- Bushing installation up to 1 in. ID diameter

- Cold working up to 1.5 in. dia in AL

- Alternate pull cylinders with varying capacities available

KEY BENEFITS

- High-Power Performance: Achieves full 3.5 -inch stroke at 15,000 lbf, in 5 seconds, reducing cycle times and maximizing productivity.

- Battery-Powered Mobility: Cuts the cord to traditional hydraulic pumps, allowing seamless movement around aircraft.

- Programmable Precision: Customizable settings for stroke, force limits, and rate.

- Adjustable stroke: allows for installation of multiple grips conditions with a single mandrel while minimizing set-up freeplay.

- Advanced Data Integration: Real-time feedback and monitoring through a pressure transducer, and position sensor ensures consistent, quality installations every time.

- Broad Compatibility: Integrates with both PartWorks and competitor tooling attachments, allowing easy interchangeability with existing legacy platforms

APPLICATIONS

- Expanded Bushings & Nut Plates: Ideal for installing expanded fit bushings, rivetless nut plates, and cold expansion processes.

- Adaptable to Many Pull Type Installations: Lockbolts, blind bolts, alignment pins, split sleeve cold-expansion, and press fit or shrink fit bushings.

WHY CHOOSE THE PFX15K

- Speed & Efficiency: Our micro-hydraulic system rivals the power of stationary pumps and delivers a full stroke at peak load in a fraction of the time of other battery-powered tools.

- Portable Power: Combines power and portability, perfect for both production and MRO environments.

- Quality Assurance: Integrated sensors ensure every installation meets precise requirements, reducing the need for post-installation checks.

USE OF PFX15K WITH

PARTWORKS PRODUCTS

Plain Bearings

The PFX15K enables precision installation of plain bushings, often used in static joints to increase load-bearing areas or in rotating joints for wear reduction. With its programmable control for force and stroke, this puller ensures secure, consistent installations, especially when converting to cold-expanded fits. The enhanced control reduces operator fatigue and improves quality assurance, ideal for high-volume, high-demand applications in the aerospace sector.

Rivetless Nut plates for Fastener Hole Repair & Production

For high-stress and fatigue-prone repairs, the PWX BPHP along with PartWorks ultra-thin walled Rivetless nut plates and bushings ensures an efficient installation for structural integration, and fatigue life enhancement conversion from traditional methods, particularly for large-diameter bushings that challenge manual installation methods.

Cold Expanded Bushings

Cold expanded bushings Installations benefit from the Precision FX’s capability to manage high installation forces while providing data feedback on the expansion process. This ensures that the cold expansion process is completed effectively, enhancing fatigue life and structural durability. The tool’s integration into cold expansion workflows alleviates traditional issues with hydraulic hoses and improves mobility, making it ideal for on wing applications or component level as needed.

Full Integration with PartWorks RepĀRTM Augmented Reality Solution

If precision engineered stress is what you desire for an installation, the PFX15K is designed to work seamlessly with RepĀRTM Augmented Reality Solution to validate that the work was done correctly and where and when it was done.

Discover the Future of Aerospace Installation

Upgrade your tooling with the PartWorks PFX15K Puller — built for high-demand applications in the aerospace industry, from OEM production lines to military MRO facilities.

Want to learn more about PartWorks products and solutions?

Please fill out and submit this form and we will be happy to answer your questions.

You can also reach us directly by phone at (404) 910-3210.